Panel Handling

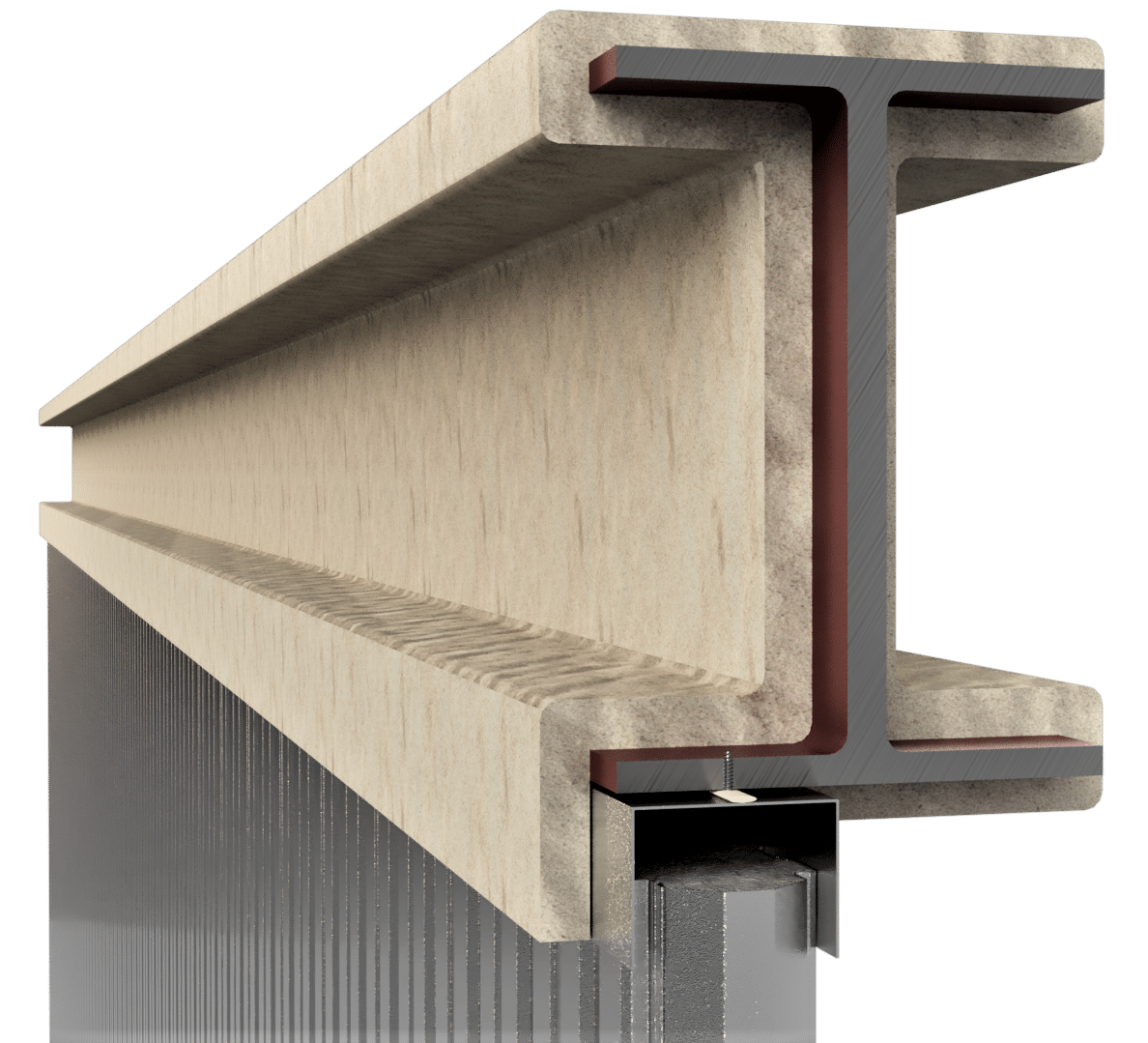

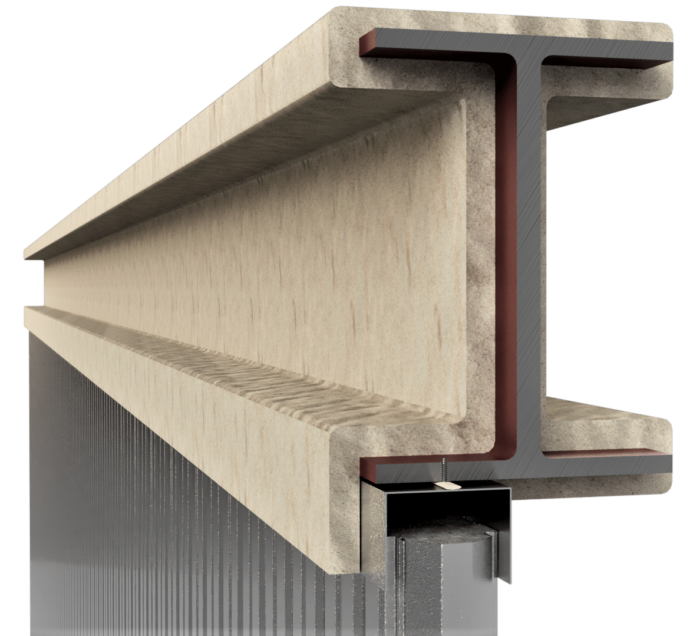

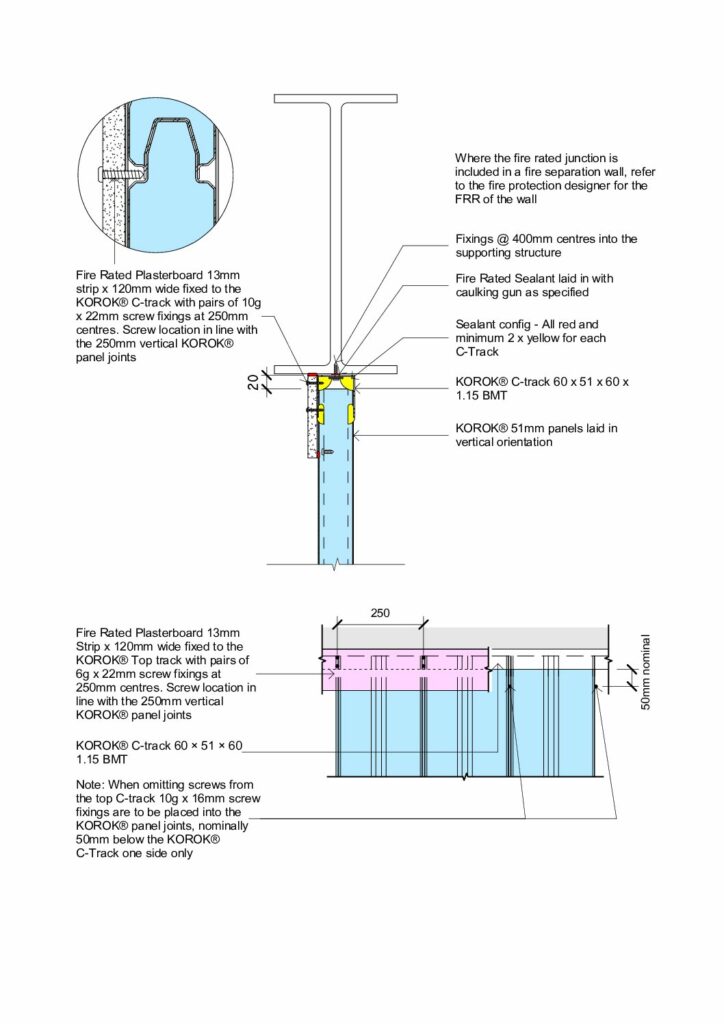

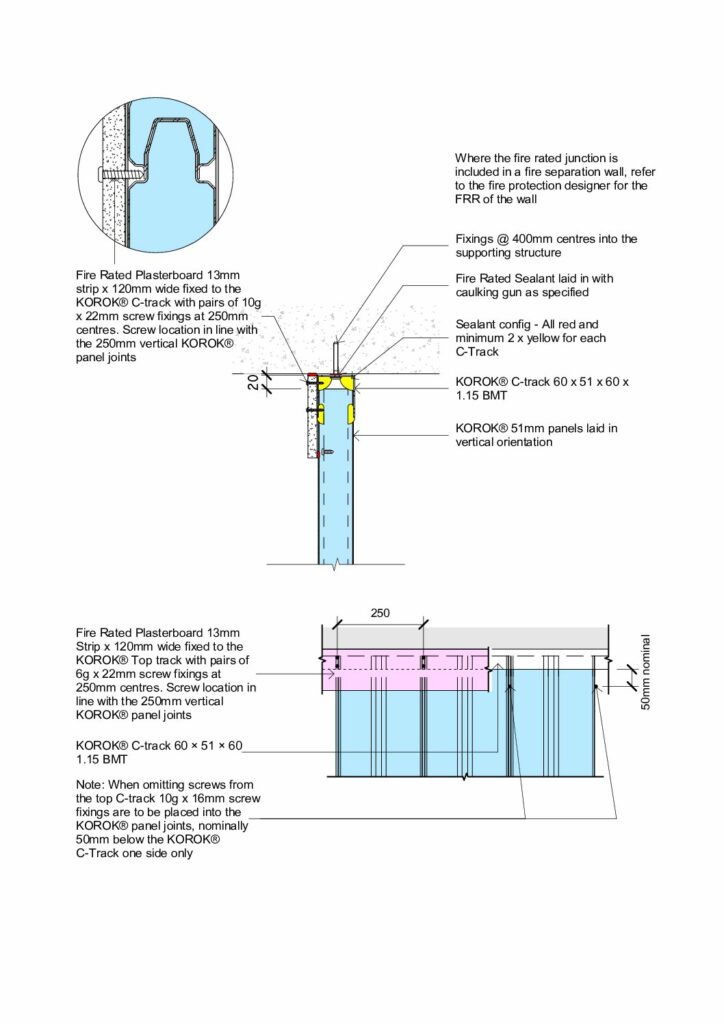

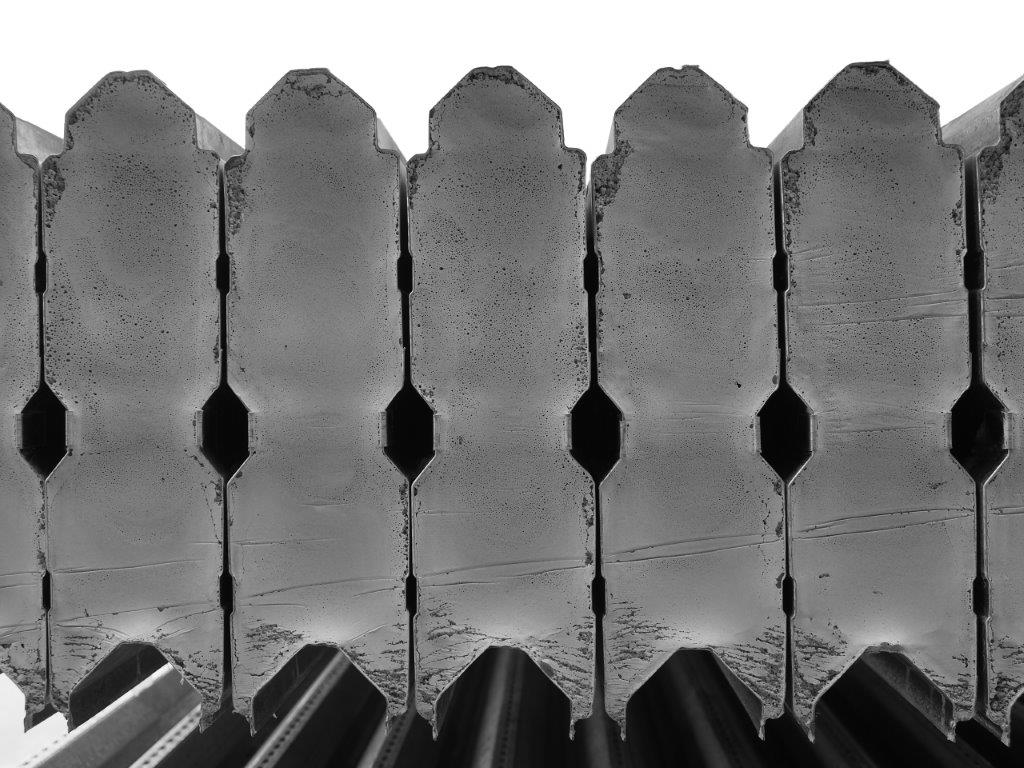

KOROK manufactures lightweight wall panels consisting of galvanised or colour steel shells filled with aerated concrete.

Generally, KOROK products are delivered to your building or other site on long trailers and articulated trucks.

Our products are packed with reasonable protection against damage during delivery, however care must be exercised during unloading.

Forklift, Hiab or crane unload is required.

GUIDELINES

Ensure packs are lifted slowly, avoiding jerking where possible.

Forklift unloading – 150mm between pack and mast.

Ensure soft slings are neatly running on the inside of the two most inner timber collars of the pack.

Ensure soft slings are running continuously from the hooks to underneath the pack and back up to the hook.

Do not loop the sling around itself with only one end connected to the hook. This may damage the panels when lifted.

Ensure you lift only one or two packs at a time.

PACK SIZES

The panels are packed in timber pallets, measuring 1200mm wide by 300mm high.

There will be 2, 4 or 6 timber pallets for each pack (depending on length), nominally spaced 1200mm apart, middled from pack centre.

Packs can be stacked up to 6 packs high and must be placed side by side or end on end, on the truck / trailer tray.

When stacking back-to-back, timber collars must butt up against each other.

The length of the pack will vary according to the length of the panel required by the customer, commonly between 2.0 and 7.0 metres in length (can be up to 9.0m).

COMMON PACK WEIGHTS

Standard 3 metre pack = 390 – 470kg (nominal); Standard 6 metre pack = 780 – 936kg (nominal).

STRAPPING DOWN PACKS

Loads must be strapped down and secured by appropriate means. Load strops are most highly recommended, allowing 12 to 16 strops for a full semi load, more for B-Train transport.

Packs are to always be strapped over timber collars. No belly straps done with plastic angles at any time.

When stacking higher than 4 packs, a second set of straps must be placed after the third pack over timber collars only, before adding further packs.

ACCESSORIES

At times, a bundle of steel C-track or Angle strips may be placed on top of the load. These may measure up to 6.0 metres in length and weigh from 10kg to 500kg depending on the quantity.

IN TRANSIT

Where possible, avoid sudden braking and jolts during transit to reduce impacts on the product.

Re-tension strops every two hours at a minimum.

UNLOADING

Forklift, Hiab or crane unload is required.

Use soft slings or forks only, no chains to be used on product.

All lifting to only be done under middle crate, closest to the bearers to take the weight.

Forklift unloading – 150mm between pack and mast.

Care must be taken on unload and storage of product, avoiding bumps and scratching.

Guidelines must be carefully followed (turn over page).

At

At