CASE STUDY

Nugget Avenue Terraces – Premium Terraced Living in Hobsonville Point, Auckland

Discover Modern Living at Nugget Avenue Terraces

Nestled in the vibrant community of Hobsonville Point, Auckland, the Nugget Avenue Terraces offer contemporary, safe, and sustainable living. This terraced housing project was designed by Construkt Architects and expertly built by Universal Homes. The project highlights the cutting-edge KOROK Intertenancy Terraced Housing System, ensuring superior fire and acoustic performance for urban living.

- Year: 2019

- Location: Auckland

- KOROK System: Intertenancy Terraced Housing Systems

- Product Used: 78mm KOROK panels

- Architect: Construkt Architects

- Builder: Universal Homes

Seamless Integration with Nature and Community

Nugget Avenue Terraces are designed to harmonize with the natural landscape of Buckley B Precinct. The homes showcase modern architectural elements, including bold colors and sustainable materials, making them a standout addition to the Hobsonville Point neighborhood. With a design that respects the land’s natural contours, these terraces offer not only aesthetic appeal but also an environmentally friendly solution.

Unmatched Safety with KOROK Intertenancy System

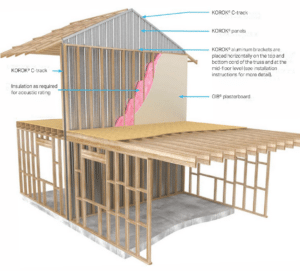

At the heart of this development is the innovative KOROK Intertenancy System, engineered for exceptional fire and acoustic protection. Traditional terraced housing systems often rely on internal linings for fire resistance, which can be compromised by penetrations. In contrast, KOROK’s system uses a robust steel and aerated concrete core, creating a highly durable barrier that significantly enhances fire protection between homes.

KOROK’s smart design ensures that in the event of a fire, its aluminum brackets melt on the fire-facing side, maintaining structural integrity on the opposite side. This safety feature gives residents peace of mind, knowing their homes are built with the highest safety standards in mind.

Why Choose KOROK for Terraced Housing?

- Fire-Rated Protection: KOROK panels create a solid barrier that withstands high temperatures, ensuring resident safety.

- Acoustic Efficiency: Enjoy quiet living spaces with superior sound insulation between homes.

- Durability and Strength: Built to last, KOROK systems offer enhanced protection against external elements, ensuring long-term durability.

- Faster Installation: With pre-finished panels, the KOROK system allows for quicker, more efficient construction, saving time and costs.

Collaboration for Quality

The success of Nugget Avenue Terraces is a result of the seamless collaboration between Construkt Architects and Universal Homes. Together, they delivered a high-quality living space that not only meets aesthetic and functional needs but also prioritizes safety, durability, and acoustic comfort.

Superior Fire and Acoustic Protection

The KOROK 78mm panels used in this project provide both fire resistance and noise reduction, making them the ideal choice for urban terraced housing developments. Their innovative design contributes to faster installation times and long-term reliability, enhancing the overall living experience.

KOROK Systems used in this project

Intertenancy Terraced Housing

In terraced housing and town houses, conventional framed wall systems rely on the internal linings for fire-resistance. Penetrating these linings potentially destroys the fire-rated barrier.